Innovative R&D

Innovative R&D

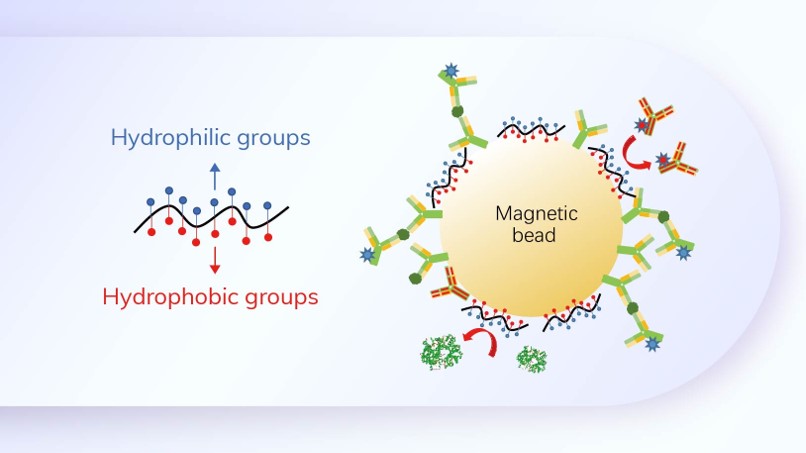

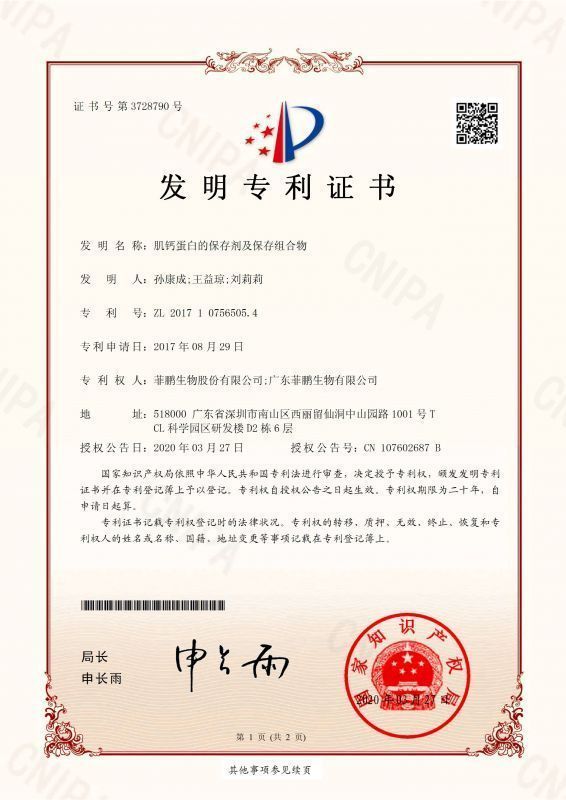

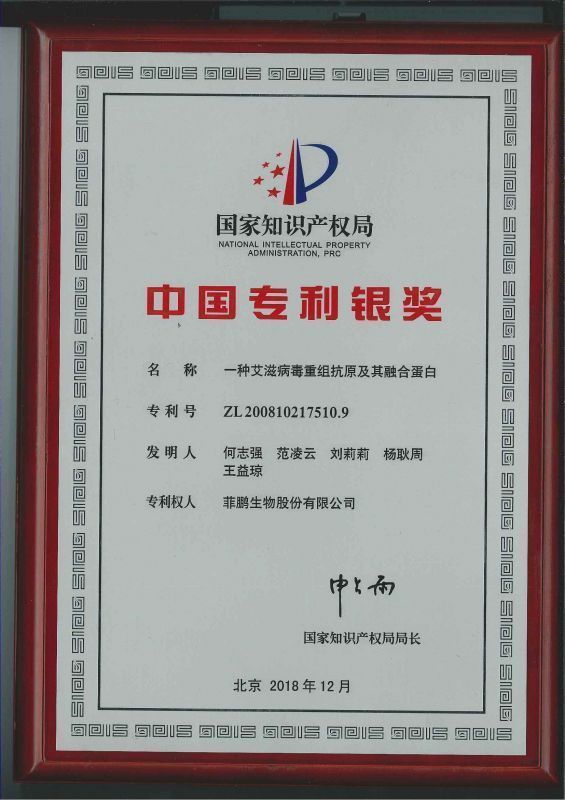

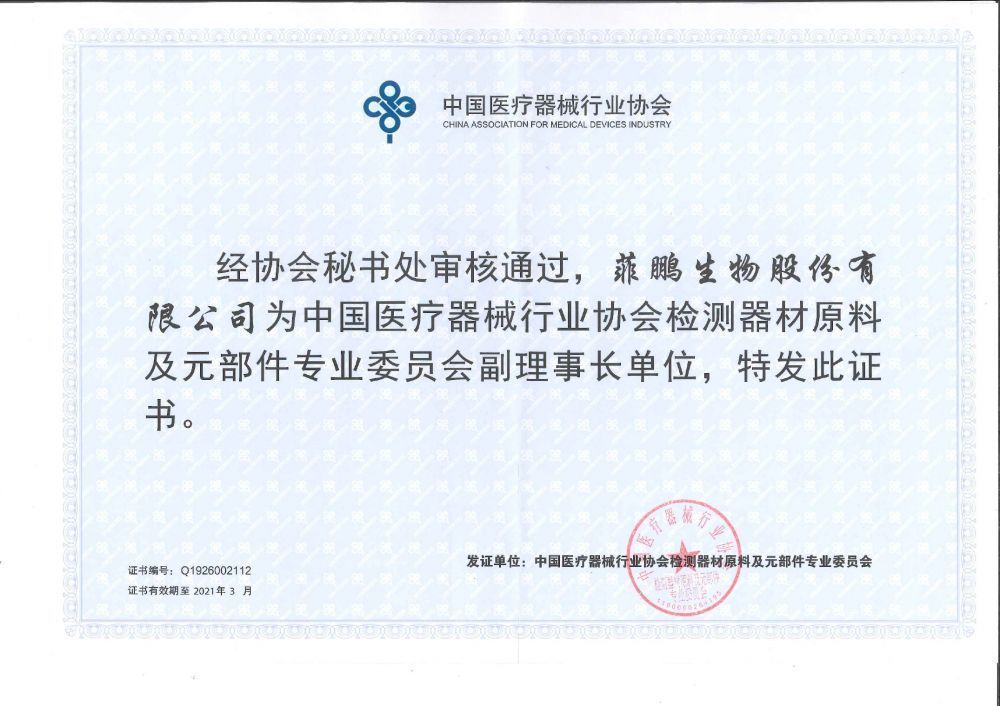

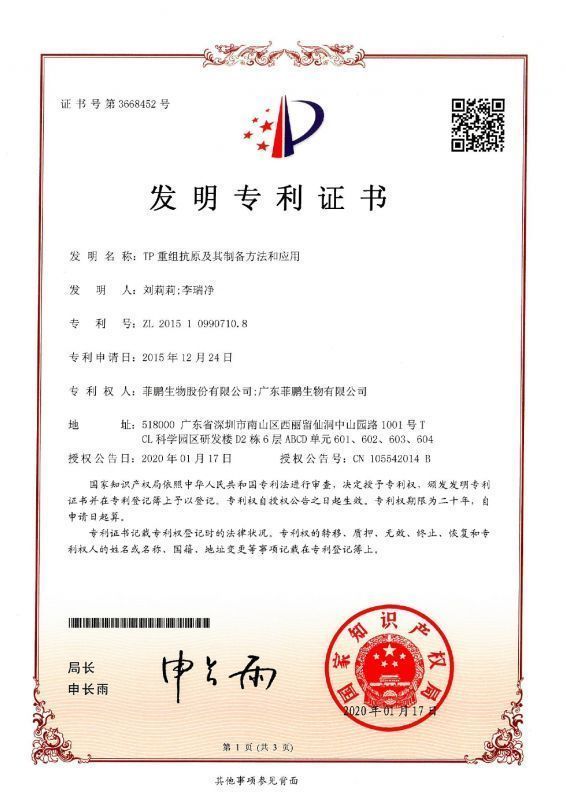

Fapon Biotech places great importance to

independent R&D, making continuous breakthroughs and iteration. We have

world-class R&D and application platforms, rich experiences in reagent

material labeling, matching and screening, reagent development debugging and

performance optimization, with an excellent technology development process

implement to meet customer needs precisely.