Overview

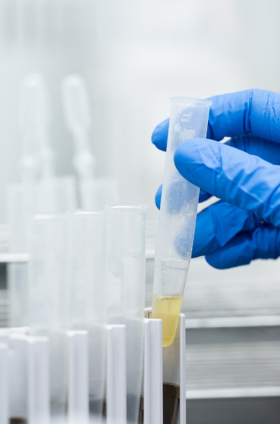

Our molecular diagnostics raw material solutions support technology platforms such as quantitative fluorescence PCR, next-generation sequencing (NGS) and isothermal nucleic acid amplification (INAAT). These solutions enable us to provide a wide array of products such as core raw materials, reagent solutions and services like customized development, technology transfer and product registration support.

Featured products

Advantages of our technologies

-

01Enzymes development

-

02Recombinant protein expression

-

03Formulation screening

-

04Production scale-up

-

05Performance evaluation

- 01

- 02

- 03

- 04

- 05

-

Enzymes development

-

Directed evolution of enzymes

We provide customized development of enzymes for specific applications.

-

AI-assisted high-throughput design

We use AI to simulate the dynamic structure of active proteins, predict the mutation sites of key amino acids, optimize molecular design, and further improve throughput and speed.

-

-

Recombinant protein expression

-

Various expression systems

We use a multitude of expression systems including our bacterial, yeast and baculovirus expression systems that can help you develop enzymes for IVD, mRNA vaccines, and scientific research.

-

High-throughput platform

Our platform is capable of recombinantly expressing 100 clones in a single batch, enabling efficient screening of top-performing enzymes.

-

Sophisticated fermentation and purification processes

Our processes ensure the robust production of enzymes with high purity and increased yields.

-

-

Formulation screening

-

Efficient screening

Our customized preservation and reaction buffers are formulated to pharmaceutical standards to ensure the stability and specificity of enzymes.

-

Enhanced enzyme modification

We functionally modify enzymes using adaptors, antibodies, nanobodies, and functional groups in organic chemistry.

-

-

Production scale-up

-

Fermentation

All our large capacity reactors, among over 100 imported bioreactors, are single-use, eliminating the risk of cross-contamination. Our single batch production capacity of up to 2,000 L is industry-leading, with high production stability and consistent process control. We are fully equipped to meet your large-scale production requirements.

-

Purification

We have multiple automated medium and large ӒKTA pure™ chromatography systems, with per batch production capacity ranging from 200 million to 1 billion units. Our industry leading production capacity caters to the varied demands from laboratories to industrial scale users.

-

-

Performance evaluation

-

Comprehensive evaluation platforms

Our raw material performance is constantly evaluated using multiple technology platforms to ensure they meet the market and batch-to-batch requirements.

-

Manufacture

-

Advanced manufacturing facility: Our GMP-certified raw materials production facilities cover over 9,000 m2.

-

Strict quality system: ISO 13485 and ISO 9001 certifications ensure the quality of our raw materials.

-

Various production scales accommodation: Our automated production lines, that include large-capacity fermentation tanks, purifiers, and lyophilizers, are designed to accommodate various production batch sizes, from small scale laboratory use to large scale industrial scale lots.

-

AEO Advanced Certified: The Authorized Economic Operator (AEO) certification further enhances the efficiency and effectiveness of our product exports.

-

Supply security: Products in regular and high demand are supplied from stock inventor, through our overseas warehouses, ensuring timely delivery.

-

Flexible delivery options: We offer flexible delivery options and can customize the specifications, packaging and logistics of raw materials.

-

Lab for novel enzymes in Boston

Lab for novel enzymes in Boston -

Lyophilization

Lyophilization -

Quantitative fluorescence PCR

Quantitative fluorescence PCR -

Lab for purification in Dongguan

Lab for purification in Dongguan -

Lab for novel enzymes in Boston

Lab for novel enzymes in Boston -

Sample preparation and filling room

Sample preparation and filling room -

Lab for novel enzymes in Boston

Lab for novel enzymes in Boston -

Lab for fermentation in Dongguan

Lab for fermentation in Dongguan -

Lab for AI-powered development of innovative enzymes

Lab for AI-powered development of innovative enzymes

Join us for a better future of IVD.

If you have any question or need any support, please fill out the information below.